Advanced technology for pure and healthy air

Through a unique combination of air recirculation, filter technology and patented plasma technology.

Advanced technology for pure and healthy air

Through a unique combination of air recirculation, filter technology and patented plasma technology.

Unique technology

How does it work?

AerSMASH eliminates harmful pollutants such as bacteria, fungi and aerosols (carrying viruses) through air recirculation and programmed plasma. This way, AerSMASH minimises the spread of pathogens such as the COVID-19 virus.

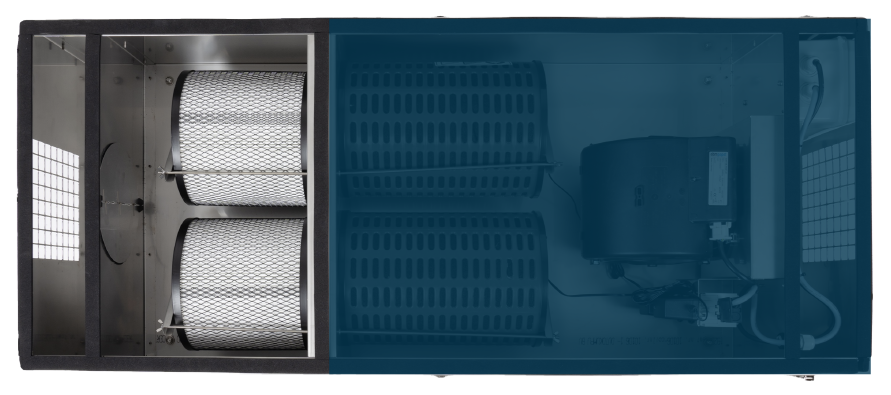

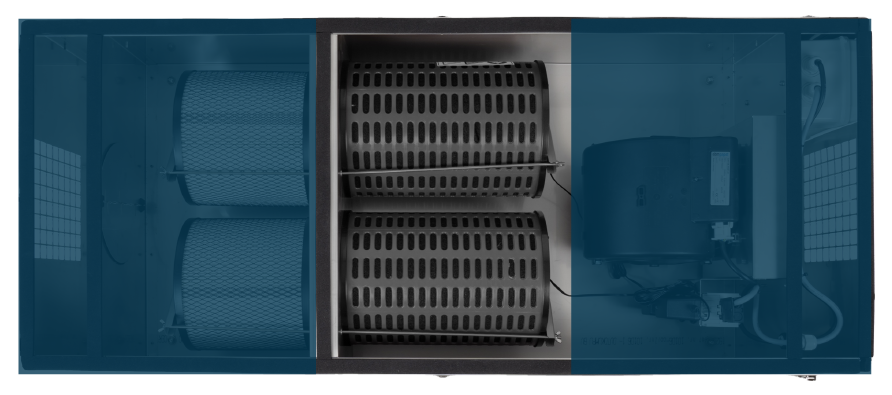

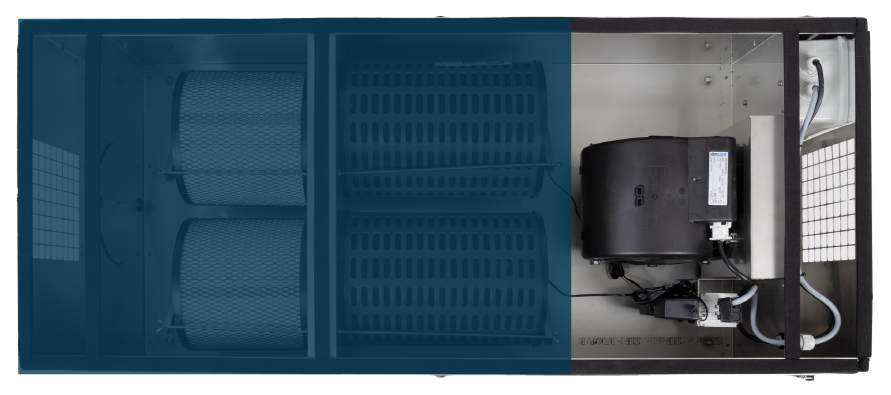

Pre-filtering

Frist, the unit sucks polluted air from the room. This goes through the HEPA pre-filter where the first coarse pollution is collected.

Plasma cartridges

The air then passes through cartridges where, by means of programmed plasma, the finer parts such as fungi and bacteria are eliminated.

Motor

The motor is set to the volume of your space. From here we blow clean air back into the space.

ADVANCED TECHNOLOGY

What is programmed plasma?

The AerSMASH unit purifies air based on a patented concept. By injecting ionised plasma, hydrogen molecules are extracted from the harmful air particles through a chemical reaction. As a result, these particles decompose and lose their harmful charge.

Depending on the amount of polluted air and the size of the room, we calculate how much plasma the unit needs. Moreover we determine the best way to install the unit or how to add it to the existing air handling system.

Why people choose AerSMASH

The best air quality

AerSMASH ensures a much higher reduction of harmful pollutants compared to regular air cleaning.

Plug and play installation

AerSMASH units are easy to connect to existing ventilation systems, but can also be installed as a standalone solution.

No blind spots

Our system reaches every corner of the room.

Save energy

AerSMASH units reduce the need for mechanical ventilation with 70%. This way, you save a lot of energy.

For every space

We provide solutions for spaces from 200m3 up to spaces in which 26.000m3 air is refreshed per hour.

High reduction harmful pollutants

The results you can achieve with AerSMASH

Minimum of 90% decrease in aerosols

95% decrease of penicillium levels

Up to a 97% decrease of harmful pollutants

results for each sector

See what AerSMASH can do for your business

Select your sector

Food

AerSMASH adds enormous value to the food sector. The AerSMASH units eliminate odours, bacteria and fungi from the air. As a result, your products stay fresh and retain their high quality for longer. Discover which results we have achieved in your sector.

Select your sector

Healthy buildings

Eliminate odours, pollen, bacteria, aerosols (carrying viruses), fungi, smoke and other harmful pollutants from the air for a healthy working and living environment. Discover which results we have achieved in your sector.

Comparing technologies

What is the difference with other air purifiers?

| Technology | Electrostatic filter / closed ionisation | Open ionisation (mono- or bi-polar) | Particle filter | HEPA | Active coal filter | Ultraviot (UVGI) | Photocatalytic oxidation | AerSMASH |

|---|---|---|---|---|---|---|---|---|

| Description | Aerosolen are electrically charged and then captured on a static medium inside the system | Ions are sent in freely in the air flow / space. Aerosols are charged, create clusters and descend into space | Pleated filters capture coarse particles in the air flow | Glass fiber filters capture fine particles in the air flow | Absorbs chemicals like gases and odours | Absorbs chemicals like gases and odours | Pathogens are exposed to UV light for deactivation | Programmed plug and play units with HEPA, Electrostatic filter, Closed ionisation and Active coal filter combined |

| Aerosol removal | ||||||||

| De-active virus | ||||||||

| Impact on gasses/VOC's | Minimum | Medium | No - minimum | Medium | ||||

| Risk on ozon | Low | Medium | Low - medium | Middelmatig tot hoog | Low | |||

| Pressure drop | Minimum | Minimum | Medium | High | High | Medium | Medium | Minimum (<60 pa) |

| Effective particle size | All | All | Above >5mu | Small | N/A | N/A | N/A | All |

Source: TVVL, Filter and purification technologies as alternative or limited ventilation capacity, release: 5 October 2020.

Frequently asked questions

84213925: Devices for filtering or air purification

The maintenance of the AerSMASH units is limited to the pre-filter and the plasma cartridge. The pre-filter should be replaced annually. The frequency of replacement of the plasma cartridge depends on the application.

Depending on the air content of the room, the amount of ventilation and the application, the optimal programming is determined for a room. An indication is included in the datasheets on our downloads page.

The units are placed in the room to create an optimal air flow in addition to any existing ventilation. The purpose is to clean the entire room. The unit can be mounted on the ceiling or wall to maintain maximum freedom of movement in the room.

AerSMASH has 2 segments: Food and Healthy Buildings. In the food industry we focus on fish, bakeries, meat processors, cheese and dairy, where reduction of bacteria, fungi and odours are the main applications. In healthy buildings, we focus on offices, schools, healthcare, sports institutions and the hospitality industry. Creating a safe working and living environment by reducing aerosols is what is achieved in healthy buildings.

The lifespan of pre-filters is highly dependent on the application. For the plasma cartridges, this varies from 2 to 5 years, depending on the application.

The technical lifespan of the units is 15 years.

AerSMASH is the designer and manufacturer of the units. The assembly takes place at a sheltered workshop located in Meppel, the Netherlands. The supply chain is mainly located in the north of the Netherlands.

The units clean the air of bacteria, fungi, odours, pollen and other harmful particles that are captured in the pre-filter. The number of particles that settle on the surface is thereby reduced.

AerSMASH reduces the number of aerosols in the air and reduces the size of the particles. As a result, the number of potential carriers in the air for viral particles is reduced to a minimum.

No, our systems run alongside the existing ventilation system. Separate units are installed that recirculate and clean the air.

By creating an ion cluster in the air, odours, bacteria and fungi are neutralised. By repeating the process, the air is made increasingly cleaner and bacteria, fungi, odours and aerosols are reduced so that an optimal air quality is achieved.

By applying a combination of programmed plasma, control and filter technology, the residual substances produced by the AerSMASH units are minimal. As a result, there is very low emission of ozone and nitrogen oxides, which makes our technology suitable for 24/7 use.

The results achieved by AerSMASH can be found on our website for all sectors. Tests have been carried out by or in collaboration with external knowledge institutes (such as the Technical University of Eindhoven) or inspection authorities.

AerSMASH prefers to work alongside the existing ventilation systems in order to achieve optimal operation. Applications on a bypass of existing ventilation systems are possible.

By carrying out a programmed process of ionisation, a stable form of plasma is realised, which leads to very small maximum amounts of ozone (<5ppm). These, if they arise, are neutralised in the system.

The cleaned air from the AerSMASH unit does not lead to an increase in the concentration of ozone in the air. Any residues such as ozone and nitrogen oxides are captured in the unit.

The power of the motors is 200W for types AS1 to 7; and 18W per plasma cartridge; the power supply for the overal unit is 220-240 V / AC.